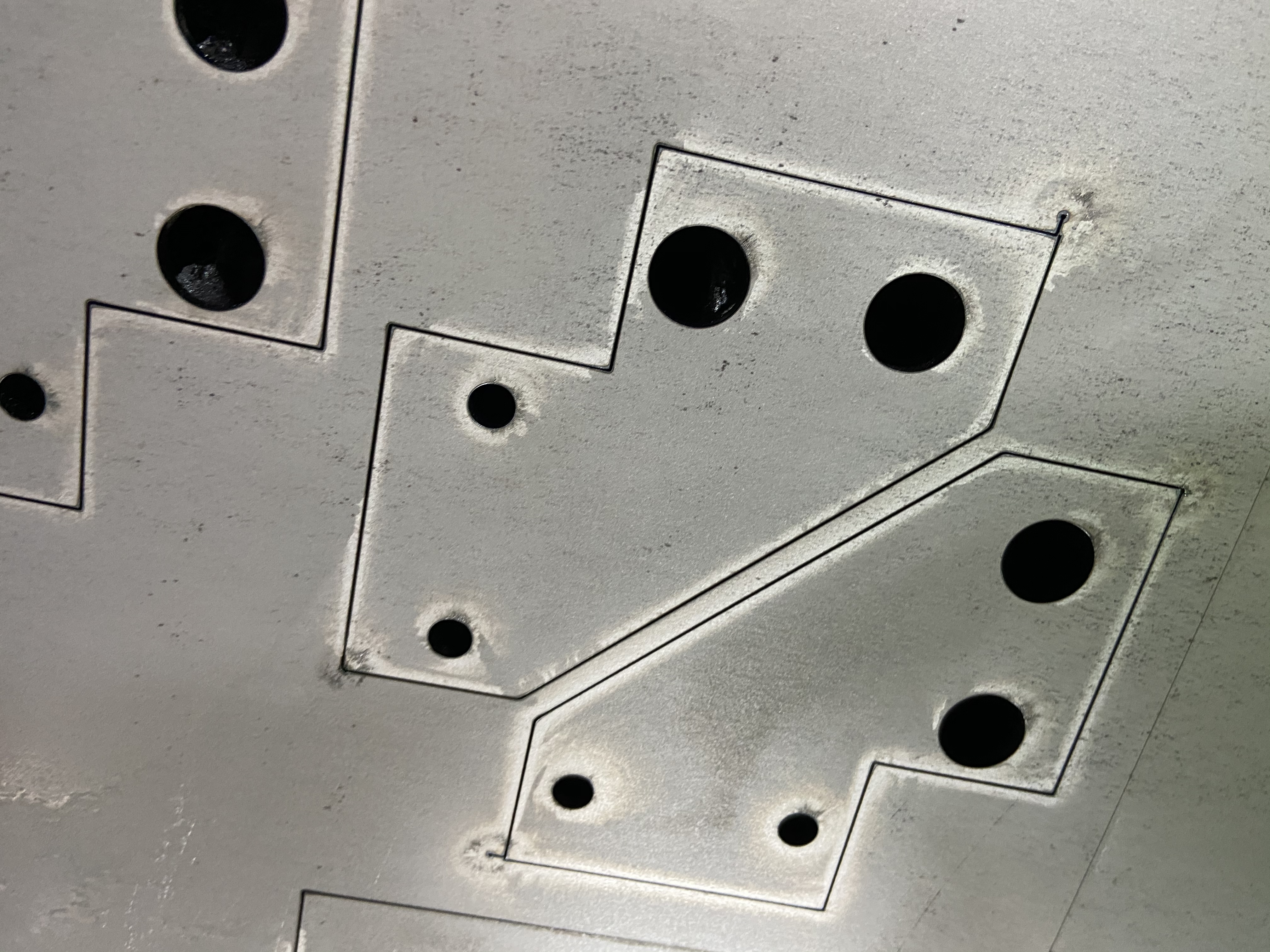

Laser cutting technology makes it possible to transfer the customer's most complicated contour specifications one-to-one onto a sheet metal format in an absolutely precise manner.

Laser cutting does not create any burrs on the workpiece edges of the laser parts that need to be laboriously removed.

Regardless of whether extremely large or small batch sizes are required, whether medium or large format, thick or thin sheet metal, with laser cutting technology we can meet the high demands of our customers in every respect.

Laser cutting of sheet metal parts and sheet metal assemblies

Sheet metal parts and sheet metal assemblies are the backbone of numerous industries, including the automotive industry, mechanical engineering, plant engineering, medical technology, the food industry and electronics manufacturing. In these industries, precision and maximum efficiency are crucial when it comes to producing these indispensable components. Laser cutting has established itself as a leading technology to meet these demanding requirements and play a key role in modern manufacturing.

The advantages of laser cutting:

High precision: Laser cutting offers unmatched precision, allowing complex shapes and fine details to be cut in sheet metal. This exceptional accuracy ensures the production of the highest quality components that meet the most stringent standards. Whether it's delicate electronic components or robust components for vehicle construction, laser cutting guarantees precision.

Speed and efficiency: Thanks to automation and impressive cutting speeds, laser cutting of sheet metal is extremely efficient. This results in time and cost savings that reduce the overall cost of your projects and especially the laser part, while increasing productivity. Complex cutting patterns and large production quantities are no problem for modern laser cutting machines, which further increases efficiency.

Versatility: Laser cutting machines are extremely versatile and can cut a wide range of materials including steel, stainless steel, aluminum, copper, brass and even titanium. This versatility makes laser cutting the optimal choice for many industries, regardless of specific material requirements. From light sheets to thick panels, laser cutting adapts to the needs of sheet metal assemblies.

Low heat effect: The laser beam cuts the sheet metal part precisely at the desired locations, thereby minimizing the heat effect on the material. This helps prevent deformation or loss of hardness and maintains the mechanical properties of the machined parts. Even sensitive materials such as stainless steel or titanium remain unchanged.

Little material loss: The extremely narrow laser cut reduces material loss on metal sheets to a minimum. This is not only economical, but also contributes to sustainability by wasting less raw material. Less waste means more environmentally friendly manufacturing.

Hardly any burr formation: When cutting metal sheets, removing burrs is one of the most common post-processing steps before the metal sheets can be delivered to the customer. Extreme burr formation occurs, especially when punching sheet metal, but this can be reduced to a minimum when laser cutting sheet metal parts.

Our high-tech laser machines:

In our company we rely on the latest laser technology, especially proven fiber lasers of the latest generation from companies like Trumpf. Our fully automated laser machines are equipped with sophisticated control systems that ensure precise and reliable production of sheet metal parts. We believe in the pursuit of excellence and take pride in providing our customers with high quality and customized solutions. Our team of experts monitors every step of the manufacturing process and uses state-of-the-art technology to ensure the individual needs of our customers and their metal assemblies are met.

World first already in use at KM Sheet Metal Processing

Prepare the weld seam and round the edges automatically when cutting on our laser machine. Preparing components for welding, automatically introducing countersinks or deburring the edges of laser parts directly on the machine? Until now, this was only possible manually. But with our laser system, this is now possible during the cutting process. We can use it to automatically introduce chamfers of up to 45° and countersinks of different sizes and to round off sharp-edged sheets. In addition to eliminating manual work steps, this has many other advantages. Until now, anyone who wanted to create slanted cutting edges on the contours of components had to manually insert these so-called chamfers into the component in an additional step using a milling machine, a grinder or an angle grinder. This process is not only labor-intensive, but also very time-consuming. Create chamfers automatically? So far, this has only been possible with more complex machines that have a special 3D cutting head. With TRUMPF’s “EdgeLine Bevel” technology, chamfers can be created automatically directly on standard laser cutting machines. The innovative technology also makes it possible for the first time to create chamfers on the inner contours of the component, which are hardly accessible to an employee with an angle grinder. We round the sharp-edged sheets directly on our laser cutting machine. The rounded edges are of high optical quality. In addition, we avoid cuts on the laser components.

Are you looking for premium sheet metal solutions?

If you are looking for high-precision and efficient solutions for laser cutting sheet metal parts and sheet metal assemblies, we are your reliable partner. Please contact us to find out more about our services and tailor-made solutions in the area of laser cutting. Our experienced team is at your disposal to answer your inquiries and work together to realize your projects.

Copyright © 2021 Wisdometal Manufacturing Co.,Ltd. All Rights Reserved.

Sitemap

Products

Blog

Custom metal products

Terms/privacy